Whether it be a data center or a fleet operator, downtime is an exceedingly expensive proposition. Predictive maintenance that leverages data using machine learning algorithms is increasingly being used across several industries including the storage industry and the automotive industry.

AI-Based Predictive Maintenance in the Automotive Industry

In the automotive industry, predictive maintenance uses AI to analyze the data gathered from in-vehicle sensors and vehicle servicing records and predict the conditions that could lead to a potential engine or part failure. The user can then get the servicing done to repair or replace the engine or part.

AI-based predictive maintenance can take away the surprise of sudden failures and unscheduled servicing. It can maximize the lifespan of the automobile and its parts. It is especially beneficial for fleet operators and logistics companies whose operations and profit margins can be severely affected when a vehicle is taken off operations. Predictive maintenance is also helpful in diagnosing the problem precisely and remotely and can further minimize the servicing time for an automobile.

Predictive maintenance solutions for automobiles are provided by Infosys, Ford, BMW, Intuceo, Questar, HMG, and IBM. The video below is about how the Infosys Vehicle Maintenance Workbench can be used for fleet maintenance, efficiency, and safety.

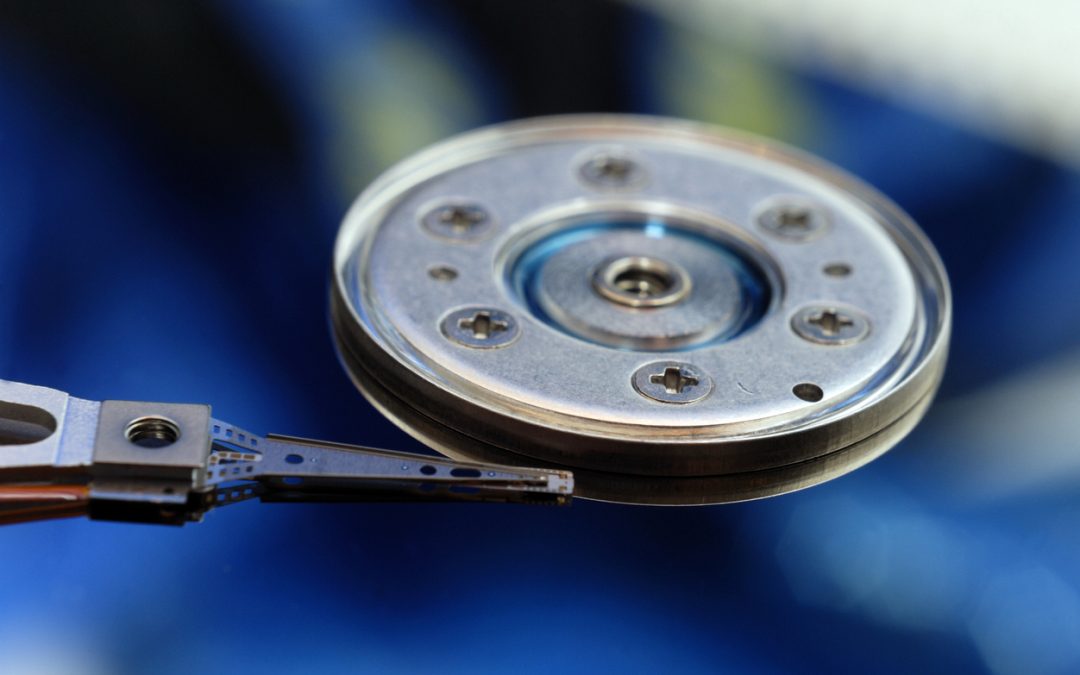

A similar solution in the storage industry is provided by the ULINK DA Drive Analyzer for the predictive maintenance of drives using AI algorithms.

QNAP and ULINK Release DA Drive Analyzer, AI-powered Drive Failure Prediction Tool for NAS

Photo Credit: PetrBonek